Introduction to Markforged

In a world where innovation drives progress, Markforged stands out as a beacon of change in the printing landscape. Imagine transforming raw materials into functional parts with unprecedented speed and precision. This is not just a dream; it’s the reality that Markforged brings to industrial applications through its cutting-edge 3D printing technology. As industries evolve, so does the demand for solutions that are both efficient and cost-effective. Enter Markforged—a company that’s redefining what it means to print in three dimensions. From prototyping to production, their capabilities promise to revolutionize how businesses operate, making them more agile and competitive than ever before. Let’s dive deeper into this game-changing technology and explore how it’s reshaping the future of manufacturing across various sectors.

The Advantages of 3D Printing for Industrial Applications

3D printing has transformed industrial applications in remarkable ways. Its ability to create intricate designs with precision reduces the need for complex tooling. This results in faster production times and lower costs.

Customization is another significant advantage. 3D printing allows manufacturers to produce tailored components on-demand, adapting quickly to specific customer needs or project requirements.

Material waste is minimized, making processes more sustainable. Traditional manufacturing often leads to excess material being discarded. With 3D printing, only the necessary amount of material is used.

Moreover, lighter parts can enhance product performance without sacrificing strength. Industries like aerospace and automotive benefit immensely from this aspect, leading to improved efficiency and fuel savings.

Rapid prototyping accelerates innovation cycles. Engineers can test ideas swiftly and refine them based on real-world data before moving into full-scale production.

How Markforged is Changing the Game

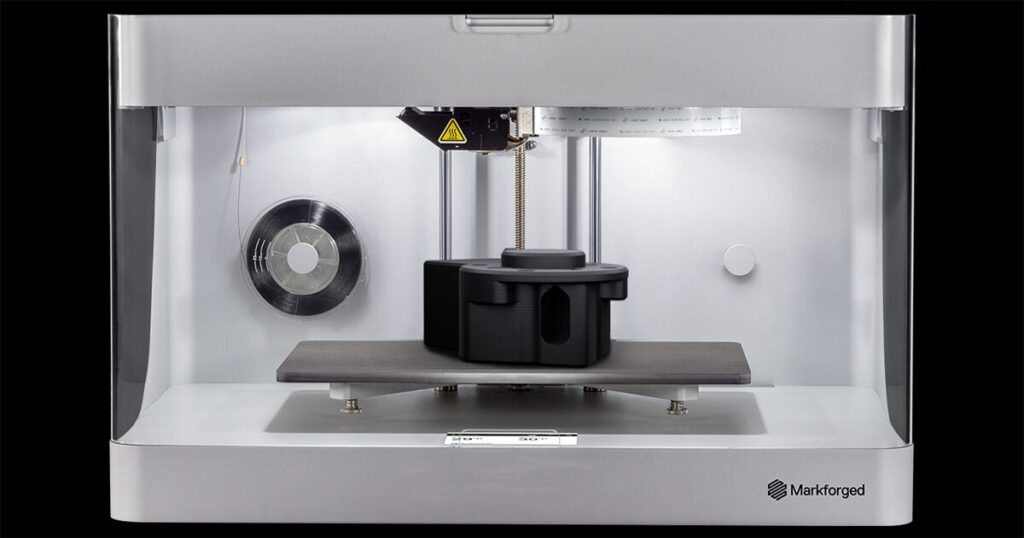

Markforged is at the forefront of 3D printing innovation. Their advanced technology allows for the creation of strong, functional parts that were once impossible to manufacture efficiently.

The unique materials they offer, such as carbon fiber and fiberglass composites, elevate 3D printing beyond plastic prototypes. This capability opens new doors for industries demanding robust components.

Additionally, Markforged’s user-friendly software simplifies the design process. Engineers can easily transition from concept to production without steep learning curves or extensive training.

Real-time monitoring and cloud integration enhance efficiency and collaboration among teams. This approach reduces downtime while ensuring quality control throughout the manufacturing process.

By combining cutting-edge materials with intuitive technology, Markforged is reshaping how businesses think about production methods. The impact on supply chains and rapid prototyping cannot be overstated—it’s a true game changer in industrial applications.

Case Studies: Real-world Examples of Mark forged’s Impact

Markforged has made waves across various industries. One standout example is in the aerospace sector. A leading manufacturer utilized Markforged’s technology to create lightweight components that reduced production costs by 30%. This shift not only streamlined their manufacturing process but also enhanced fuel efficiency.

In the automotive realm, a major player turned to Markforged for rapid prototyping. By using carbon fiber reinforced parts, they accelerated their design cycles significantly. This innovation allowed them to bring new models to market months ahead of schedule.

Healthcare also benefits from Markforged’s solutions. A medical device company produced custom surgical tools that fit perfectly with unique patient needs. The ability to print on-demand minimized waste and improved operational efficiency.

These case studies highlight how diverse sectors have harnessed the power of Markforged’s advanced printing technology, driving tangible results and setting new industry standards.

The Future of 3D Printing and Mark forged’s Role in it

The future of 3D printing is brimming with possibilities. As industries evolve, the demand for efficient and adaptable manufacturing processes grows. Markforged stands at the forefront of this transformation.

With its innovative technology, Markforged empowers businesses to create strong, lightweight parts on-demand. This capability not only reduces lead times but also lowers costs significantly. The integration of advanced materials like carbon fiber further enhances product durability.

Looking ahead, we can expect continued advancements in software and automation within the Markforged ecosystem. These developments will likely streamline workflows even more.

As companies seek sustainable solutions, additive manufacturing presents a compelling alternative. With less material waste and energy consumption compared to traditional methods, Markforged aligns perfectly with eco-conscious initiatives.

It’s an exciting time for both 3D printing and those who embrace it—Markforged is set to play a pivotal role in shaping that narrative.

Potential Challenges and Limitations of Mark forged

While Markforged is at the forefront of 3D printing innovation, it faces several challenges. One significant limitation is material constraints. Although their composite materials offer impressive strength and durability, options are still limited compared to traditional manufacturing.

Additionally, the technology can be cost-prohibitive for smaller businesses. Initial investments in printers and materials might deter potential users who are unsure about long-term benefits.

Another challenge lies in scaling production. High-quality prints require time and precision, which could slow down output in high-demand environments.

Furthermore, there’s a learning curve associated with operating these advanced machines. Users need training to maximize efficiency and minimize errors during the printing process.

Concerns over intellectual property protection arise when using digital designs for manufacturing. Companies must navigate this landscape carefully to avoid infringement issues while leveraging new technologies effectively.

Conclusion: Why Mark forged is Worth Investing In

Markforged stands at the forefront of 3D printing technology, transforming how industries approach manufacturing and design. The advantages offered by their unique processes are undeniable—cost reduction, faster production times, and the ability to create intricate designs all contribute to a more efficient workflow.

The game-changing capabilities of Markforged products enhance operational flexibility while meeting specific industry needs. Their innovative use of materials allows companies to produce parts that were once deemed impossible or prohibitively expensive.

Real-world applications showcase Markforged’s impact across various sectors—from aerospace to automotive. Companies using their technology have reported significant improvements in performance and productivity, proving that investing in this solution can yield substantial returns.

Looking ahead, the future is bright for both 3D printing as a whole and Markforged specifically. As industries continue to evolve and demand quicker turnaround times with high-quality outputs, Markforged is poised to lead this charge.

However, potential challenges remain; understanding these limitations will be crucial for businesses considering an investment in this technology.

The benefits far outweigh any drawbacks when you consider efficiency gains and innovation potential introduced by Markforged solutions. Investing in their technology could redefine your business operations while placing you ahead of competitors who hesitate at adopting such transformative advancements.